Richlite

Paper Composite Panels

Richlite is an FSC® certified product, made from post-consumer recycled paper. Sheets of paper are stacked up and saturated with a thermoset resin, then heat and pressure are applied. The resin then thermosets permanently with zero off-gassing. Learn more about how Richlite is made.

First used in 1943, the U.S. military made drop boxes out of Richlite. Because these boxes were dropped from supply planes, they needed to be durable and impervious to water. After World War II, Richlite was used for industrial applications at Boeing Airlines. Because of Richlite's durability and the way that it machines just like metal, Boeing has used Richlite for machine parts on their airplanes. Later on the material was used for skate ramps due to its smooth, flexible makeup.

Richlite has become a popular option for interior and exterior architectural surfaces and furniture. The durable, waterproof material is perfect for exterior cladding and rainscreens, but is also aesthetically pleasing enough for interior wall paneling, countertops and cabinetry.

Applications

- Counters & Table Tops

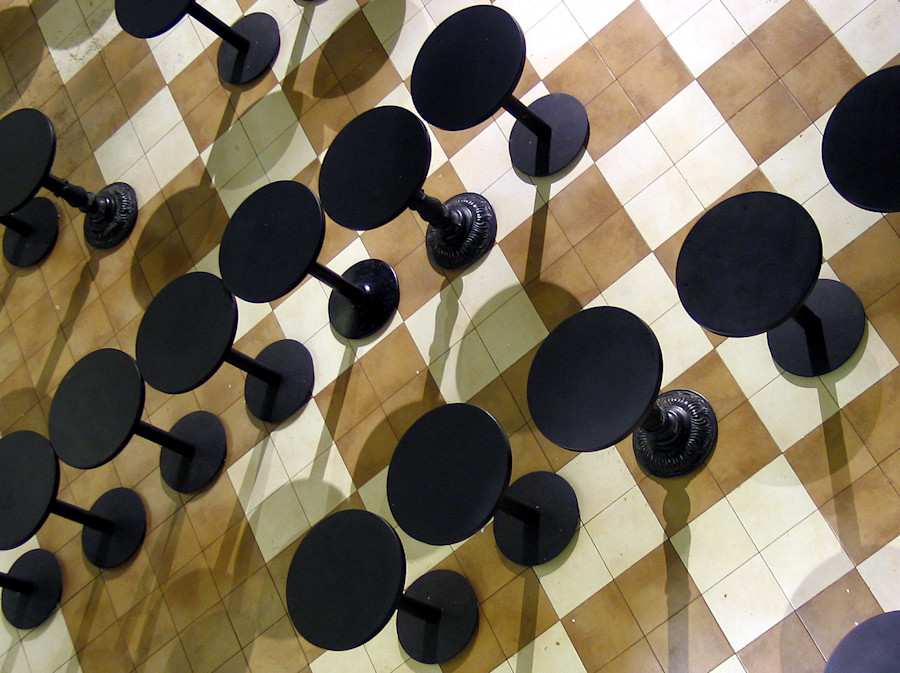

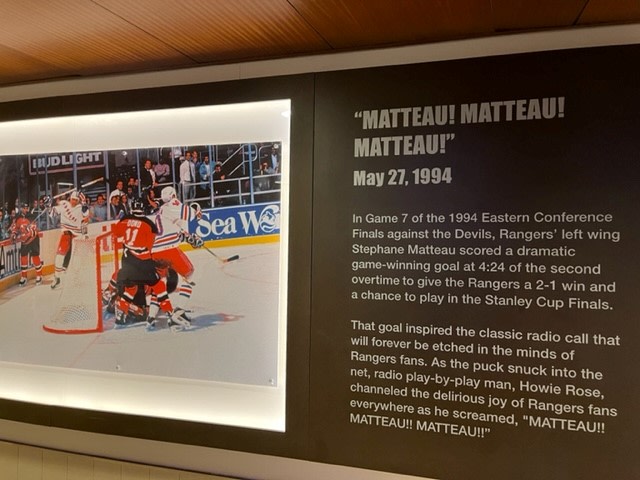

- Restaurant Surfaces & Furniture

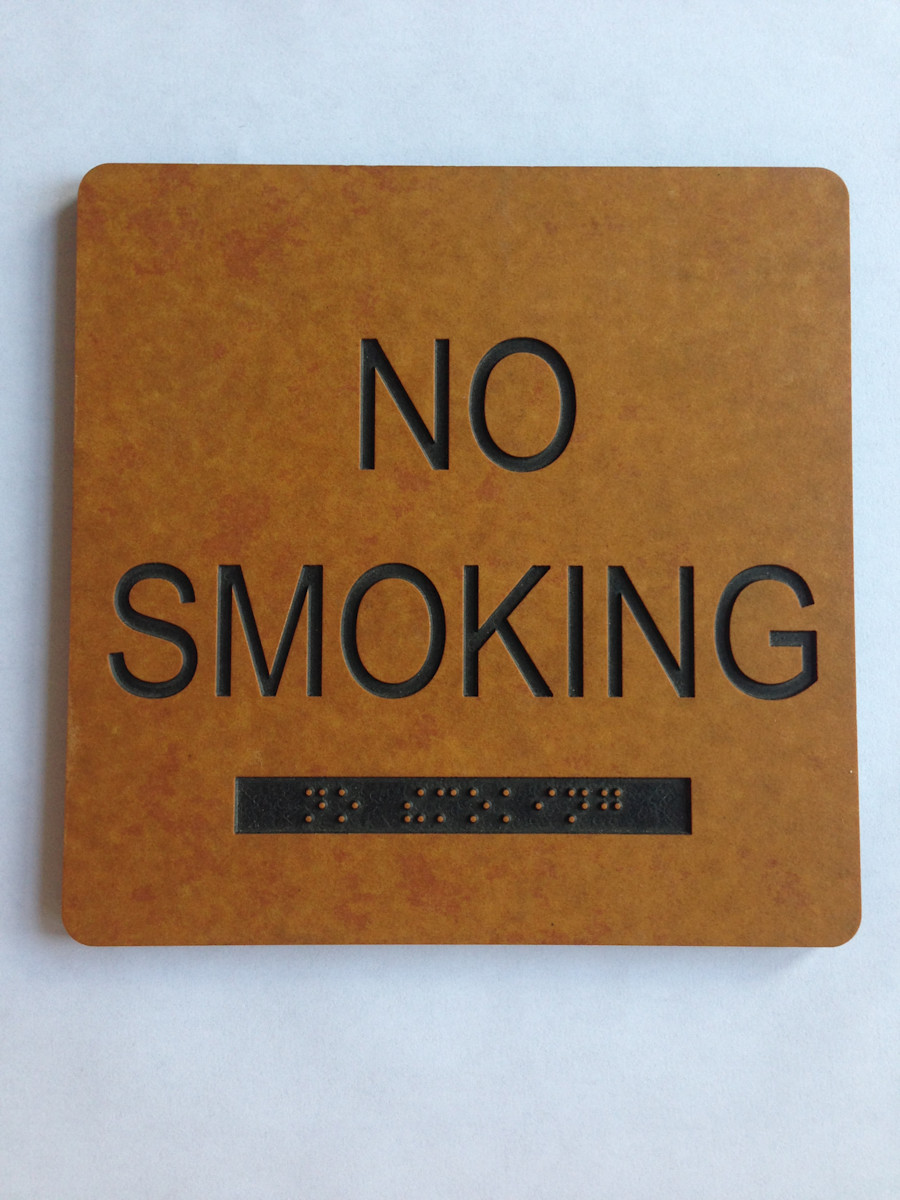

- Retail Surfaces & Fixtures

- Kitchen & Bath Surfaces

- Interior Paneling

- Exterior Façade & Cladding

- Industrial & OEM Applications

- Flooring & Stair Treads

- Skateboard Ramps & Surfaces

- Guitar Fretboards

Benefits

- Durable

- Heat Resistant up to 350°F

- Chemical & Stain Resistant

- Naturally antimicrobial (JIS 2801)

- Non-Toxic & Odorless

- Naturally Warm

- Milled with Standard Tools

- Dense & Machinable

- Beautiful Patina

- Extended Cantilevers & Long Spans

- Made in the USA

Certifications

- FSC® Certified

- Class A Fire Rated

- Declare Red List Approved

- Potential LEED® Credits

- Kosher Certified

- GreenGuard® Certified

- AIA CEU Available

- NSF Certified Options

- Richlite's FSC number: NC-COC-002292

- EcoSupply FSC number: NC-COC-001604

Size Options

- 5’ x 12’

- 5’ x 10’

- 4’ x 12’

- 4’ x 10’

- Thicknesses range from 1/8” to 3”

Product Lines

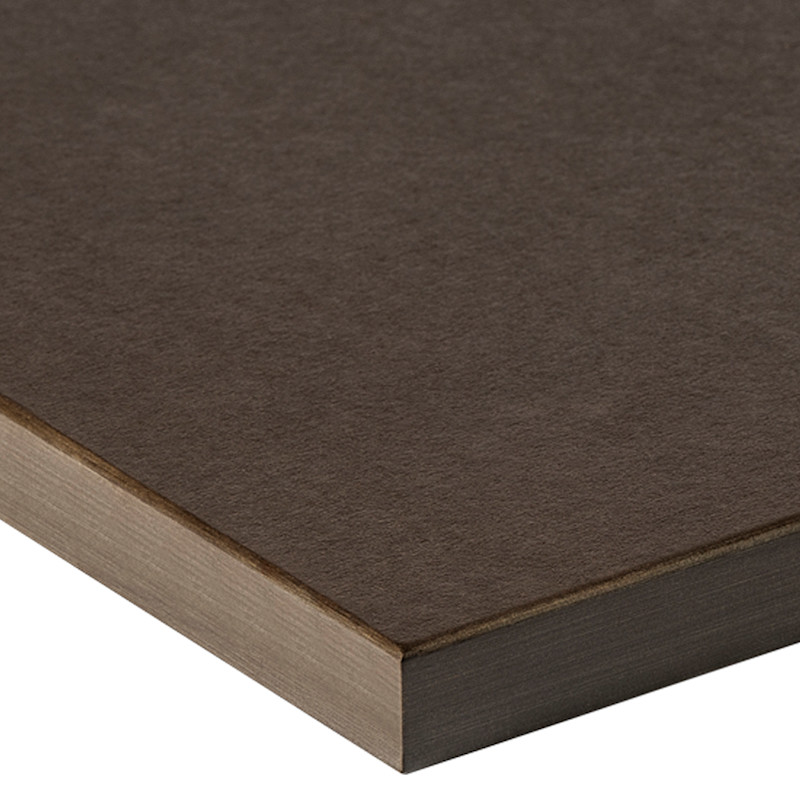

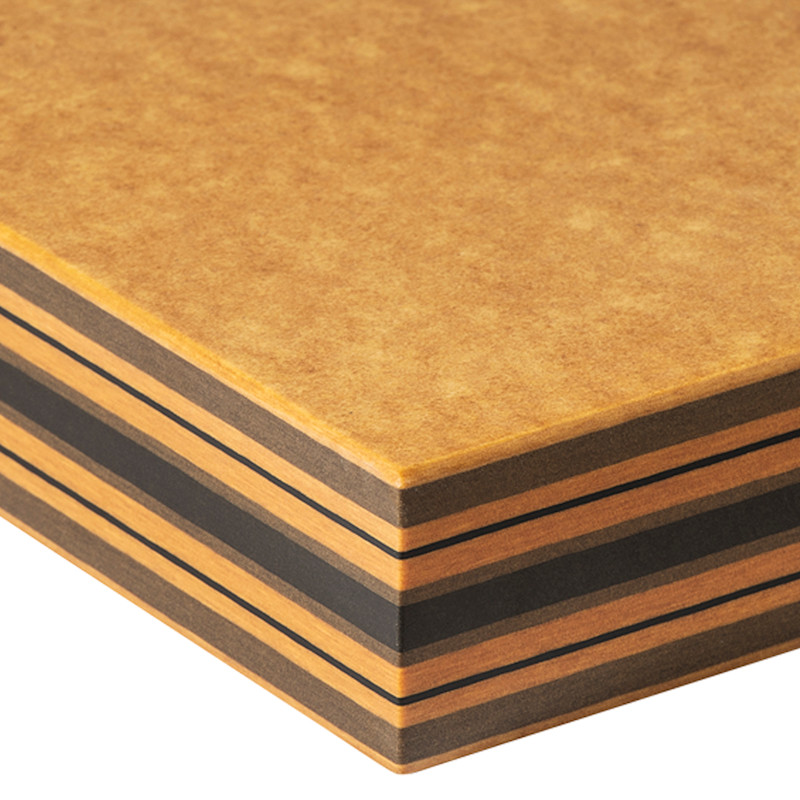

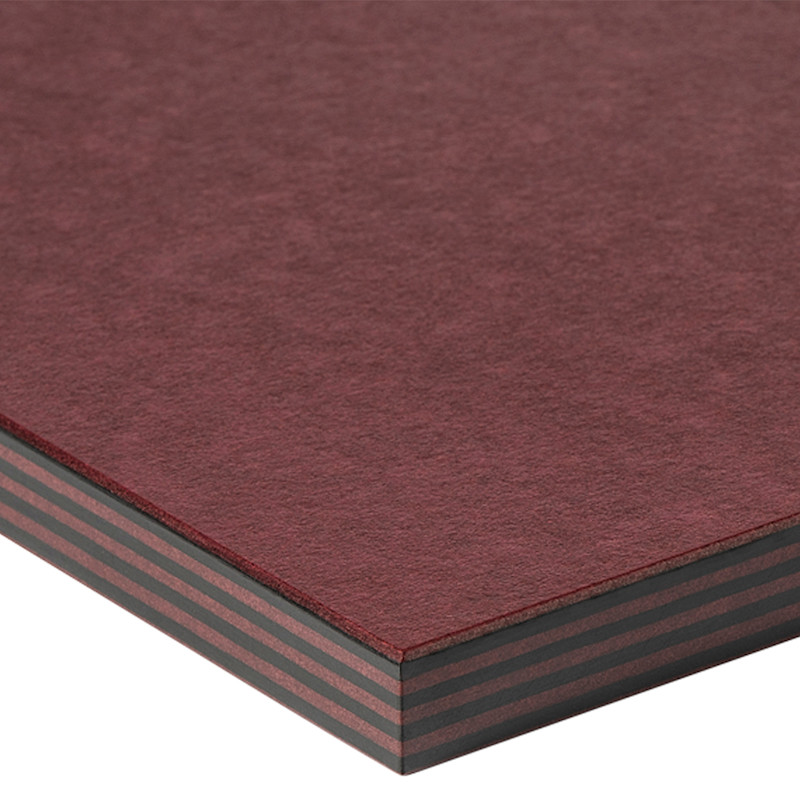

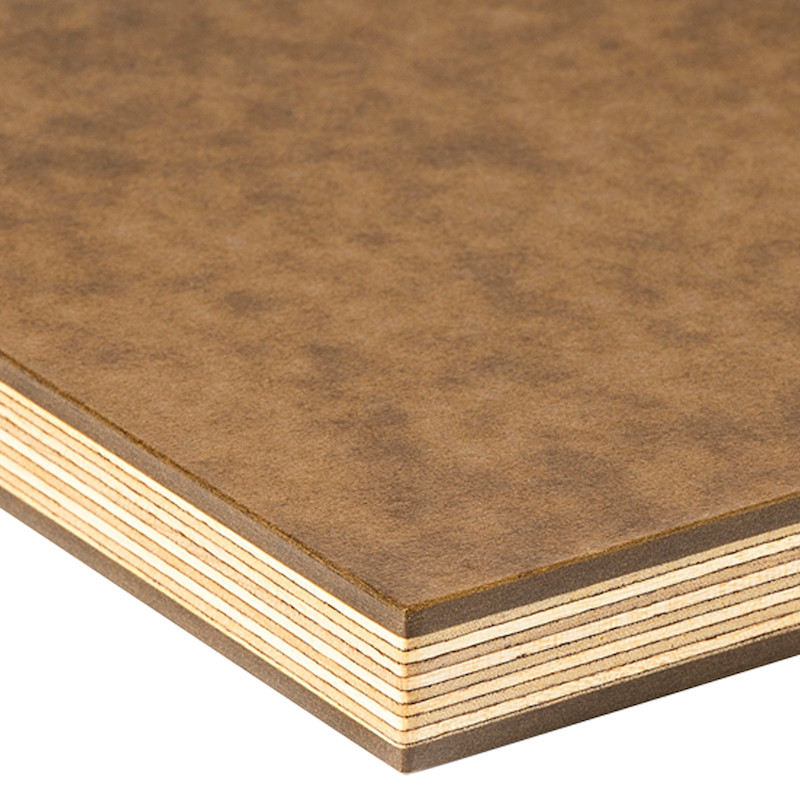

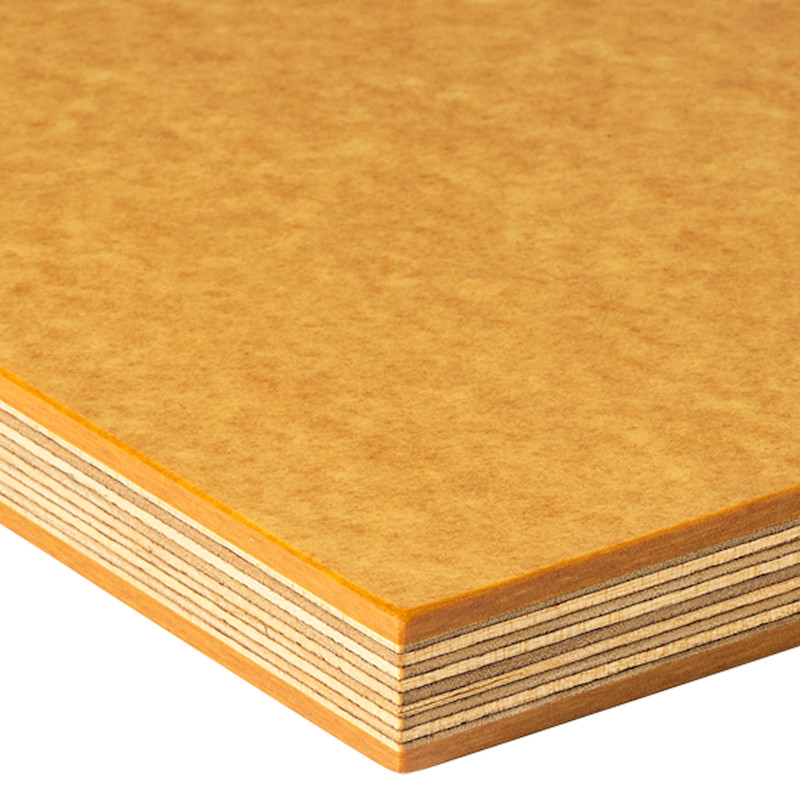

As Richlite ages, its color will become darker, richer, warmer and more dramatic. Richlite has a "mottled" appearance, due to the variation occurring naturally within the fibers of the paper that Richlite is composed of. This is less apparent in dark colors, however, the mottled appearance is still present.

Important Note: Richlite panel orders come with factory finish, see the information under Applied Finishes for more details.

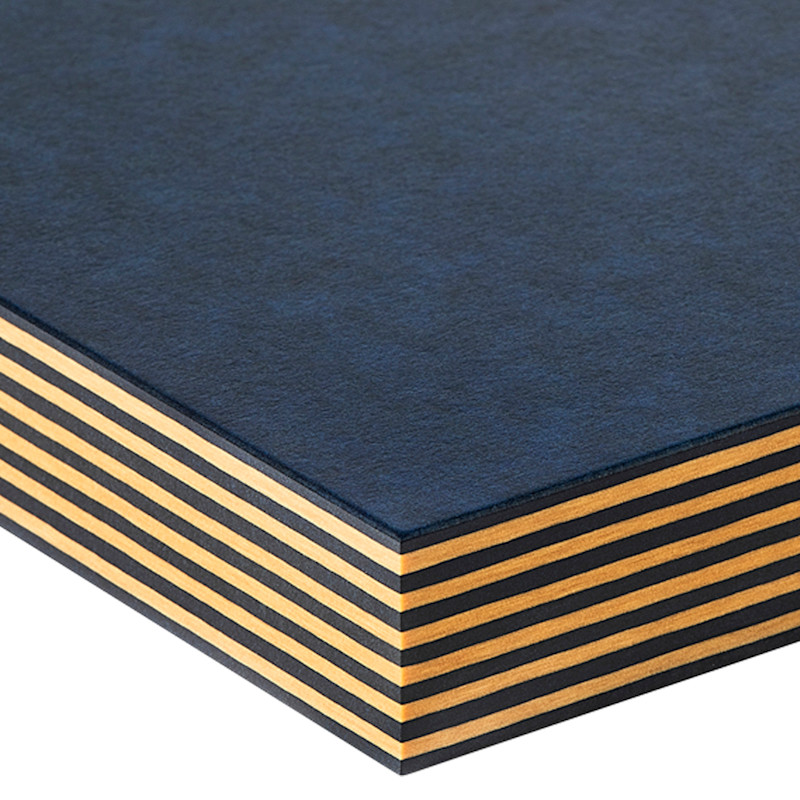

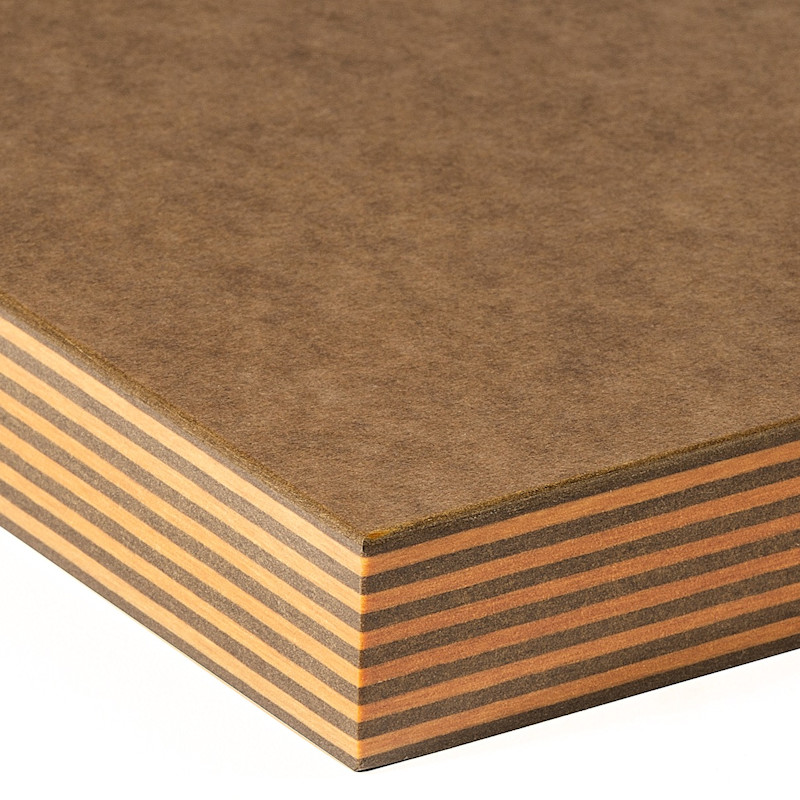

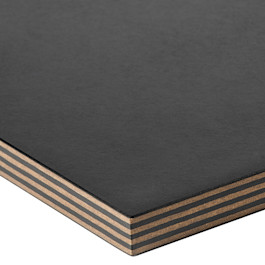

Northwest Collection

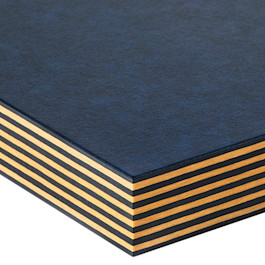

Richlite's Northwest line is available in FSC® Certified and recycled colors named after landmarks near Richlite's headquarters in Tacoma, Washington; Grays Harbor, Chocolate Glacier, Blue Canyon, Redstone, Black Diamond, Browns Point, Maple Valley (formerly r100) and Rosedale (NEW!).

Heritage Collection

Richlite’s original color, Natural, and the milestone products of Slate and r50 represent the company’s rich history. The Heritage Series is NSF certified.

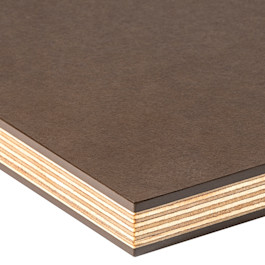

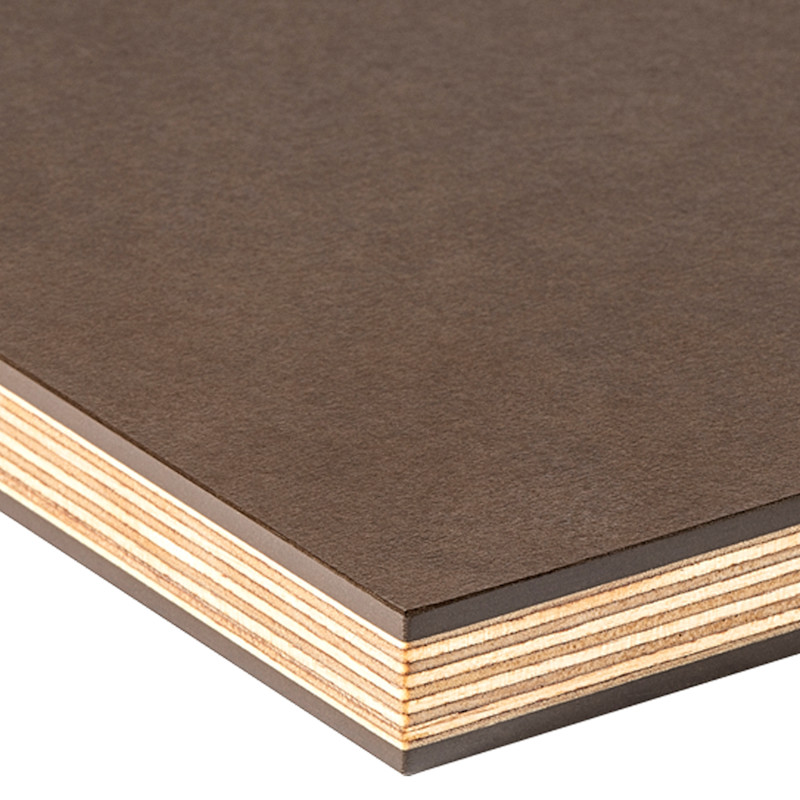

Cascade Collection

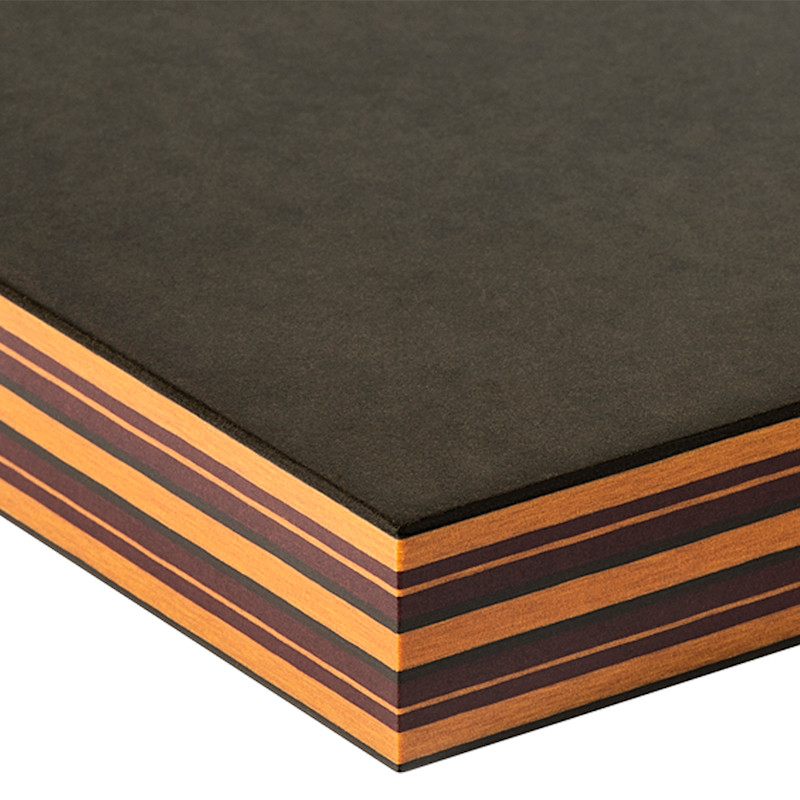

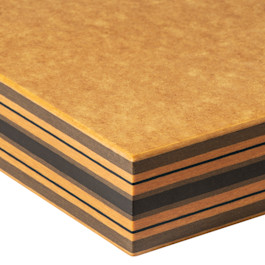

The Cascade Mountain Range is the inspiration for Richlite Company's line of layered products. Rainier, Shasta, Adams, Hood, Little Tahoma and Baker are the six tallest peaks of the Cascade Mountain Range.

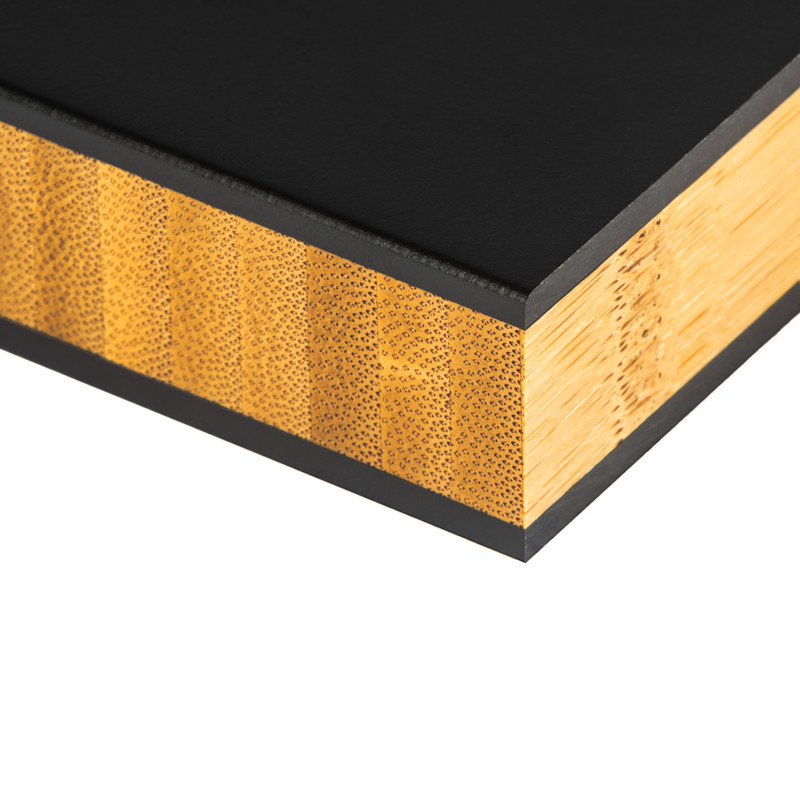

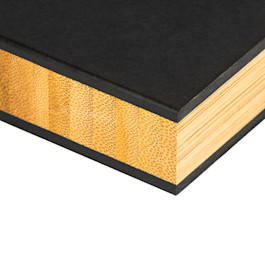

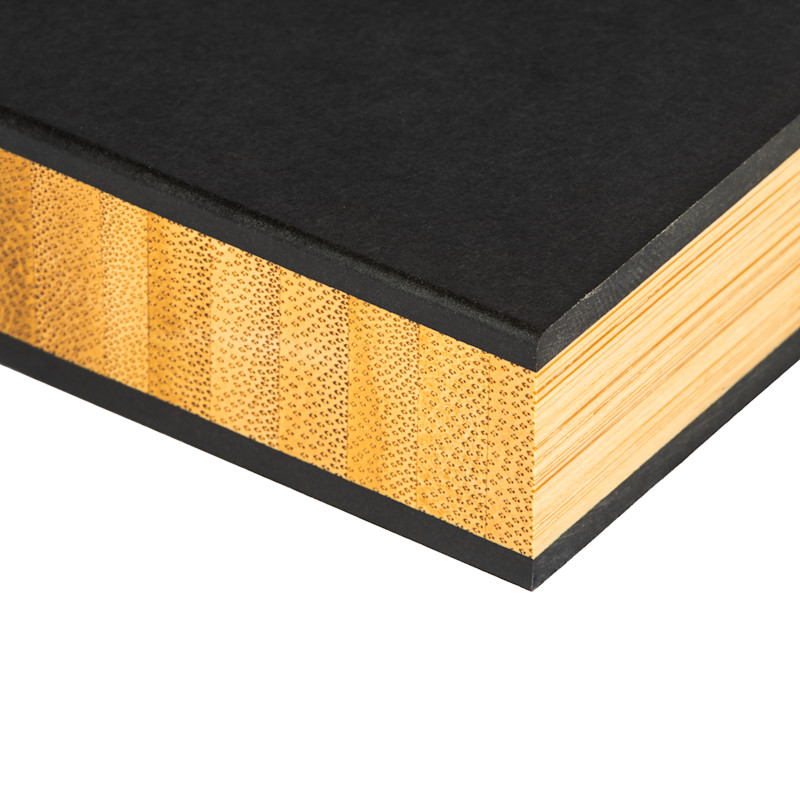

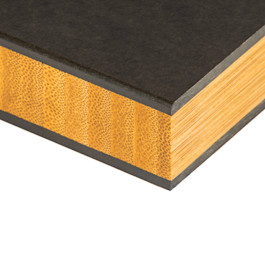

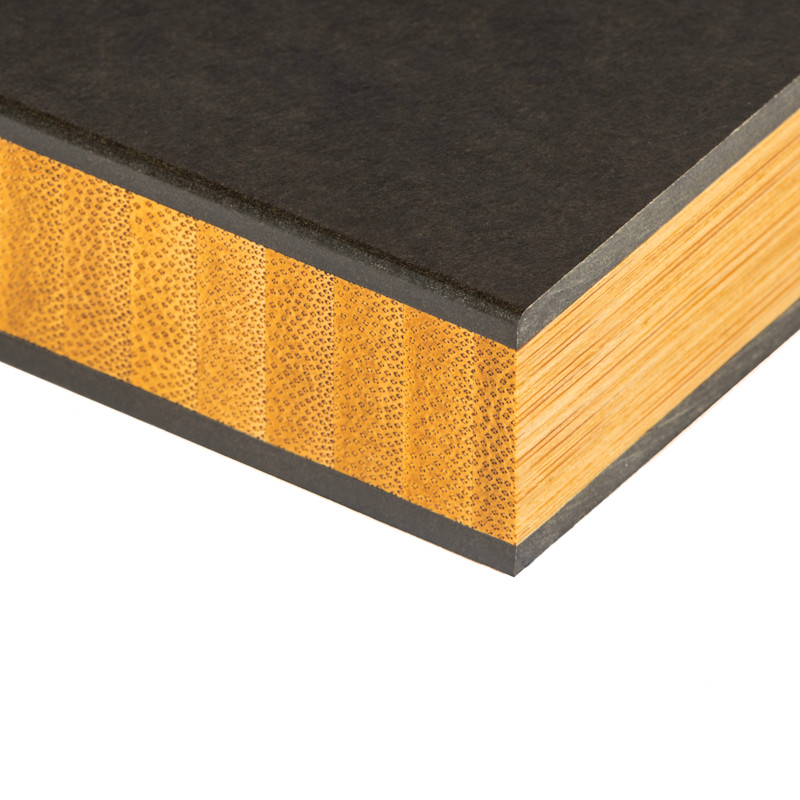

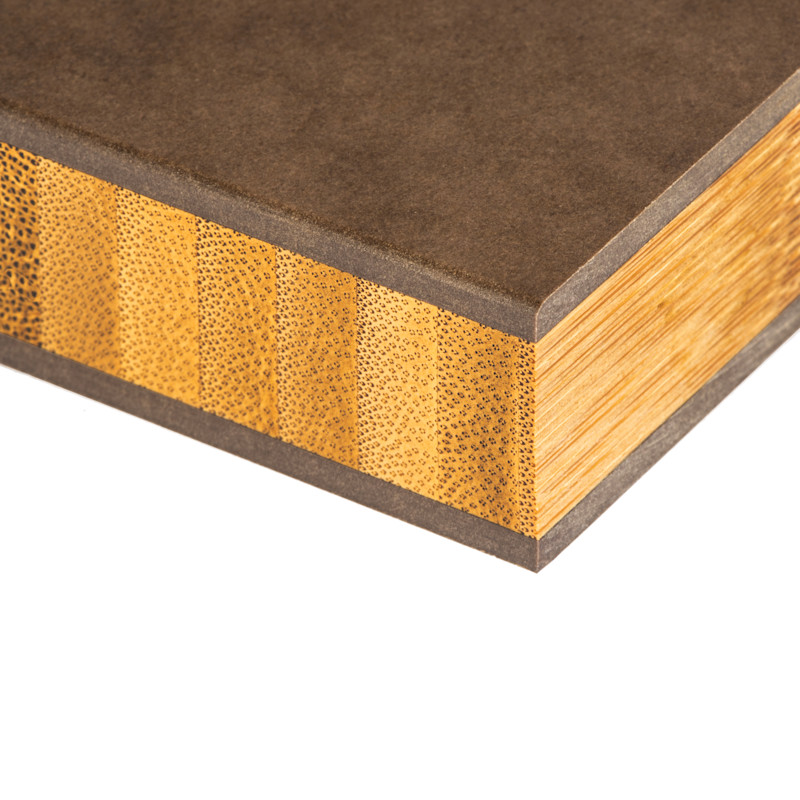

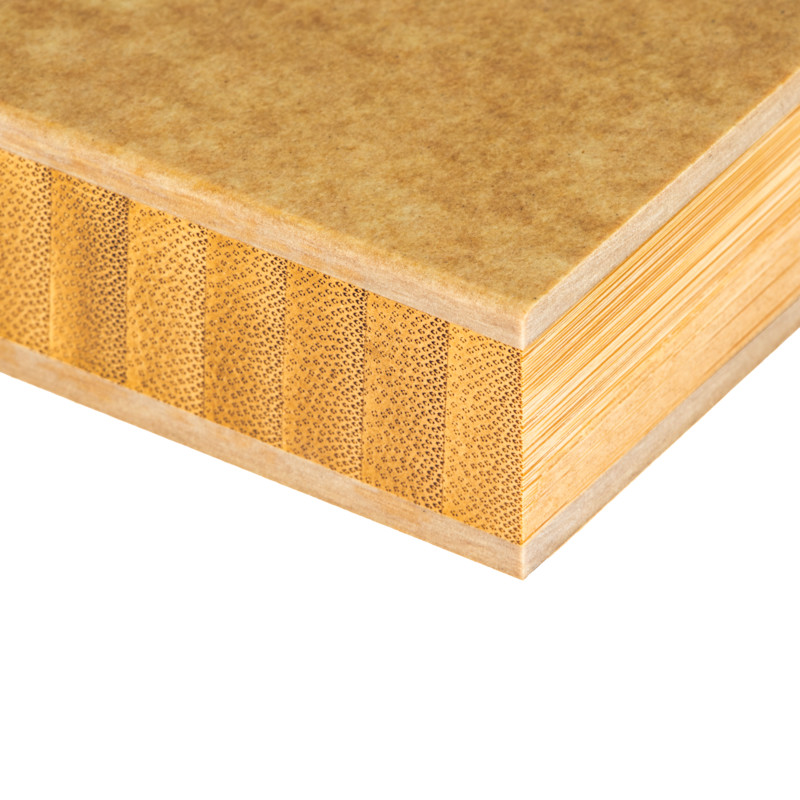

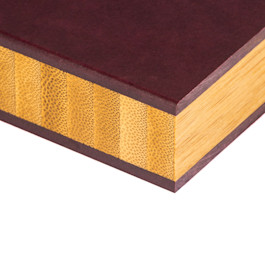

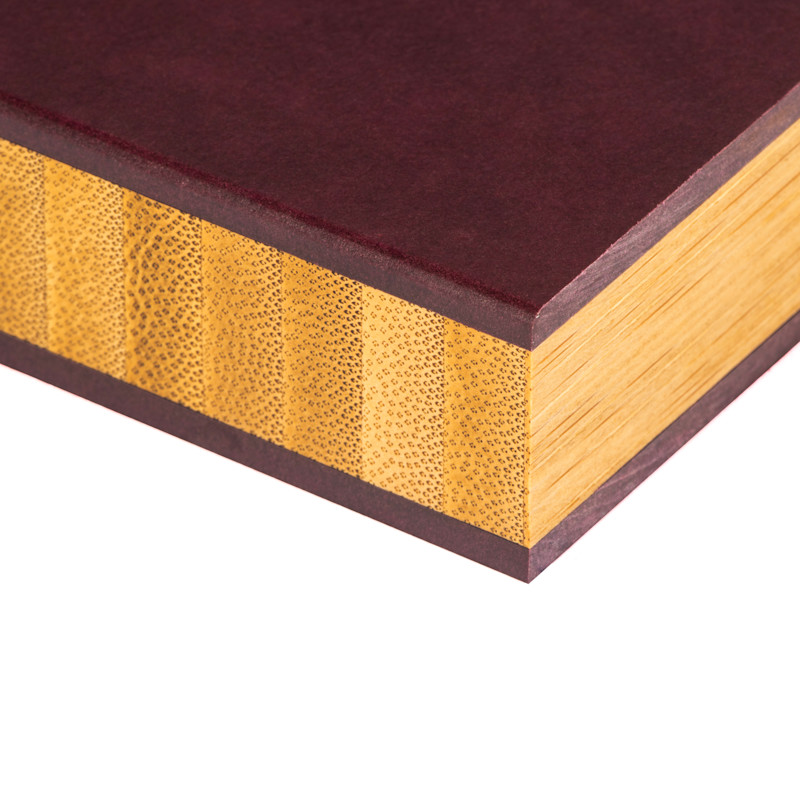

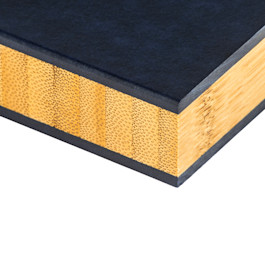

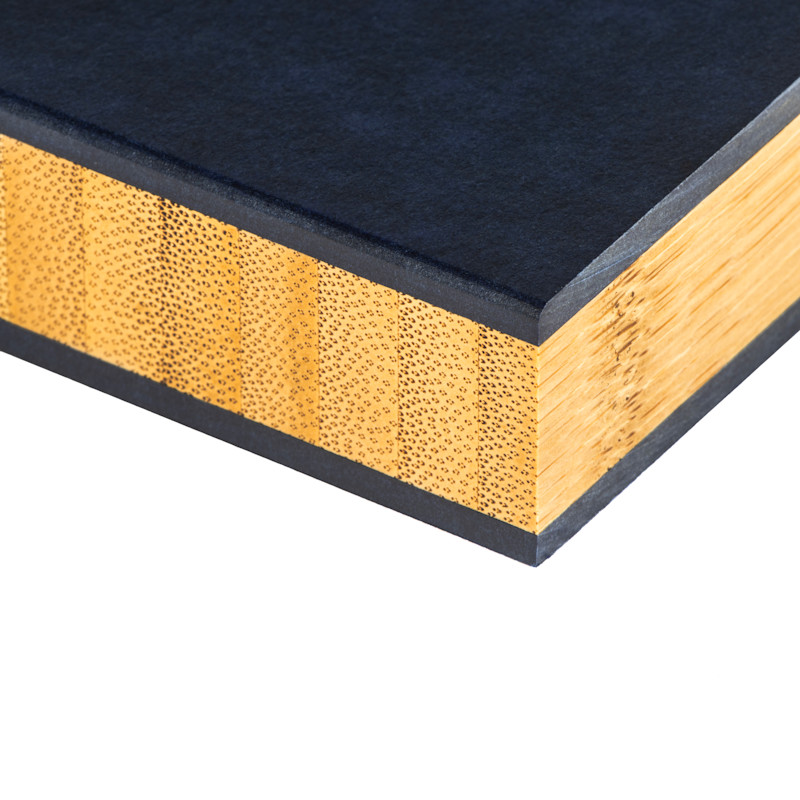

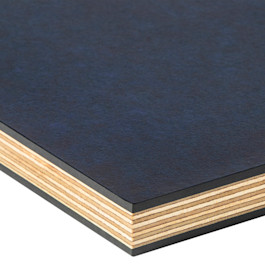

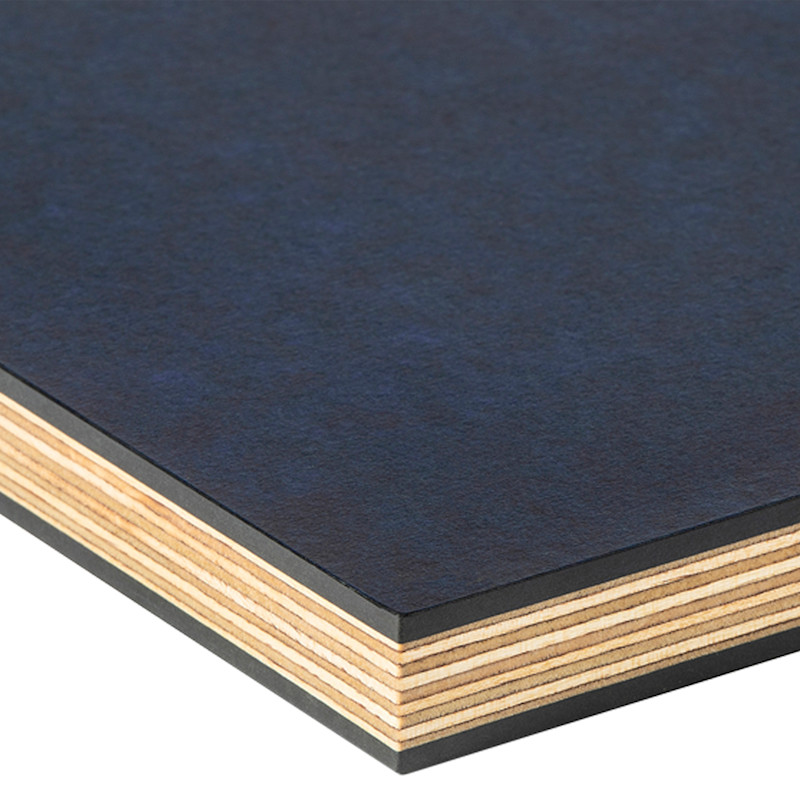

Stratum Bamboo Collection

Richlite Stratum Bamboo is an incredibly stable and balanced product that embeds Bamboo ply between contrasting layers of paper.

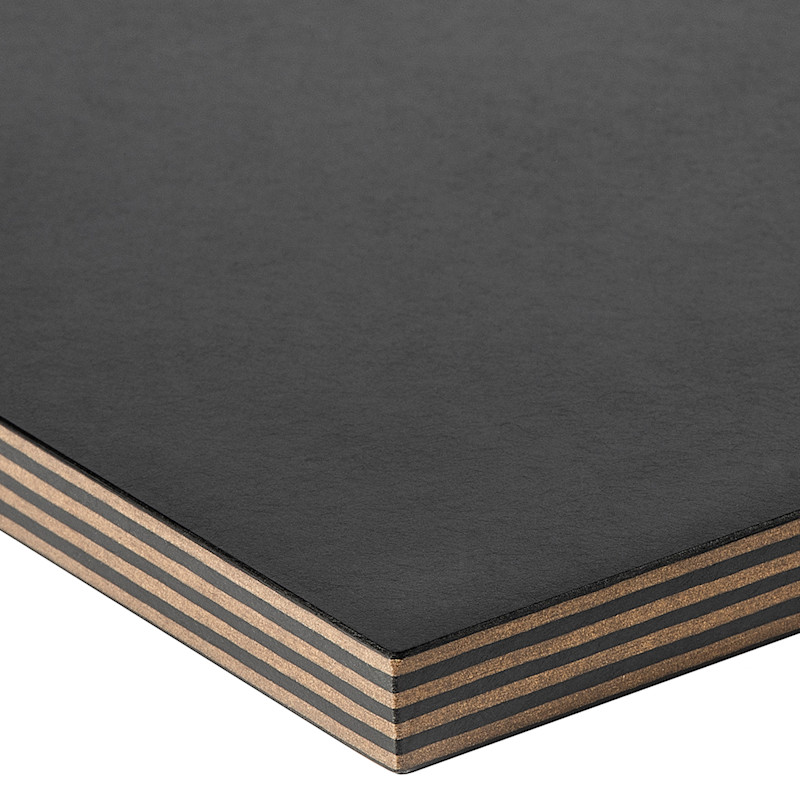

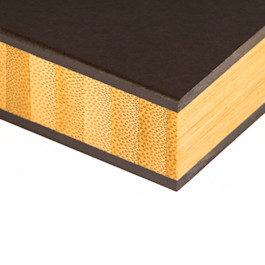

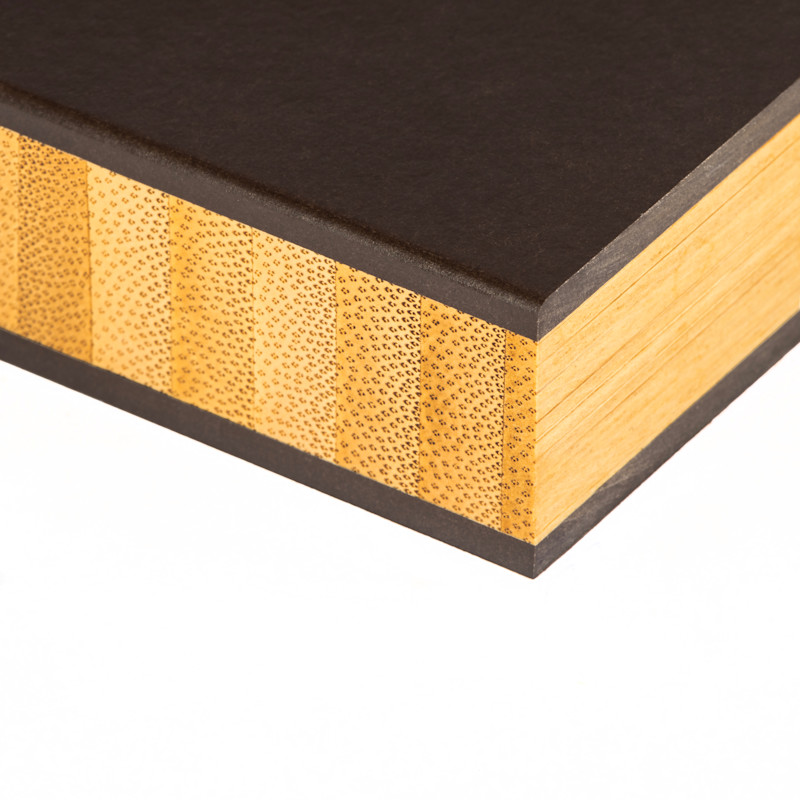

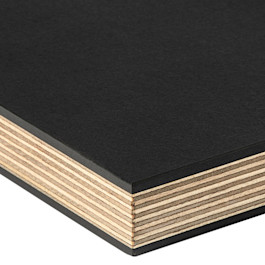

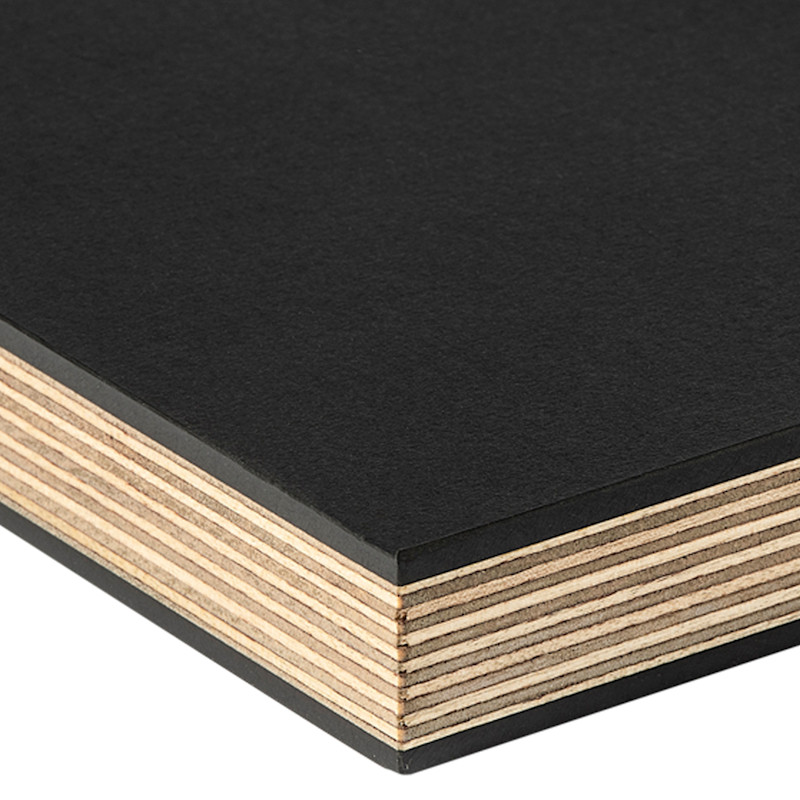

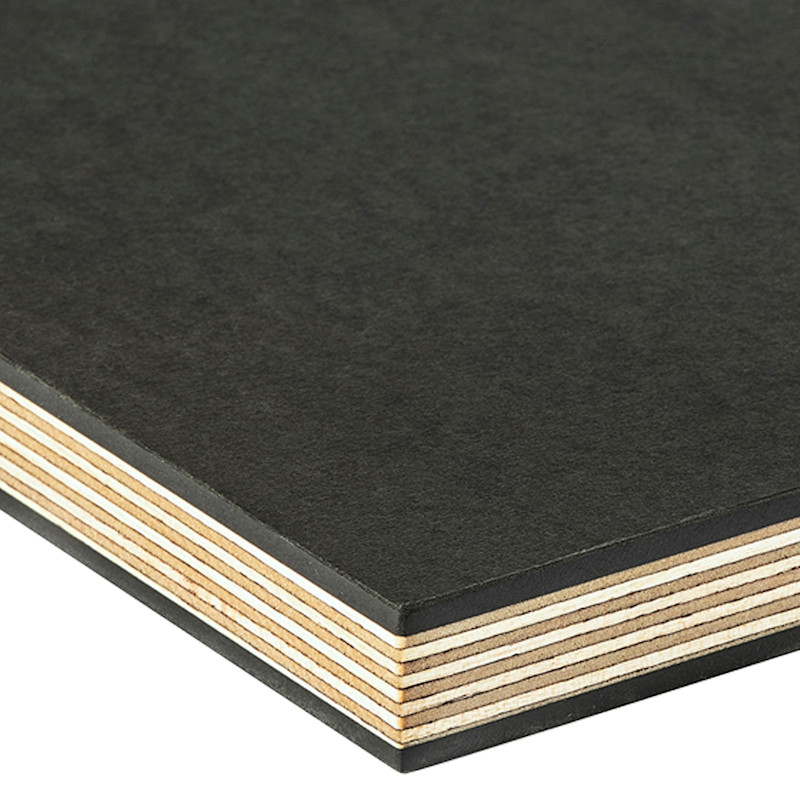

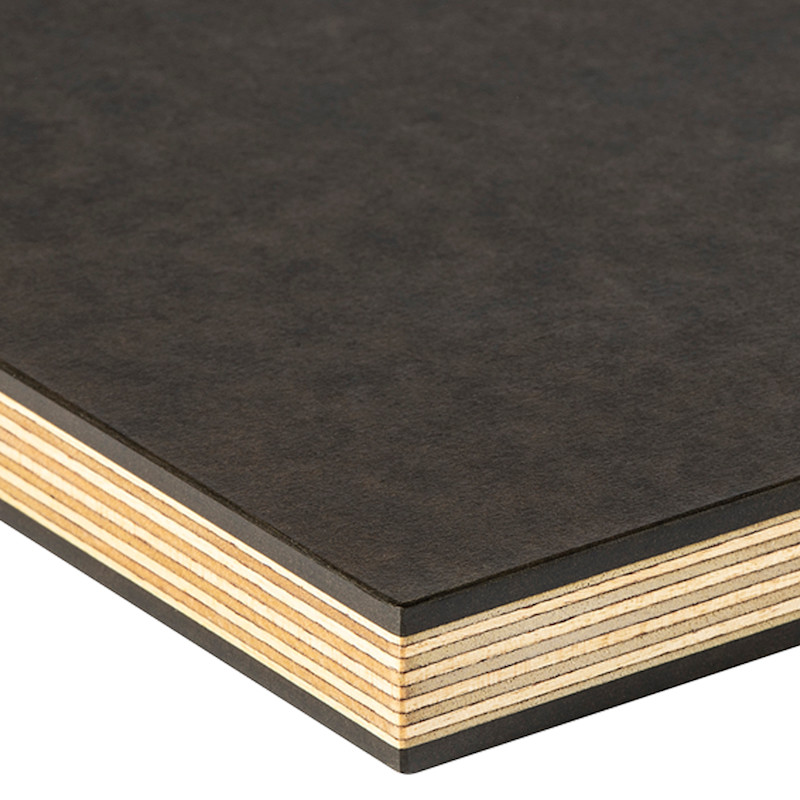

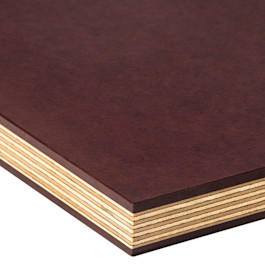

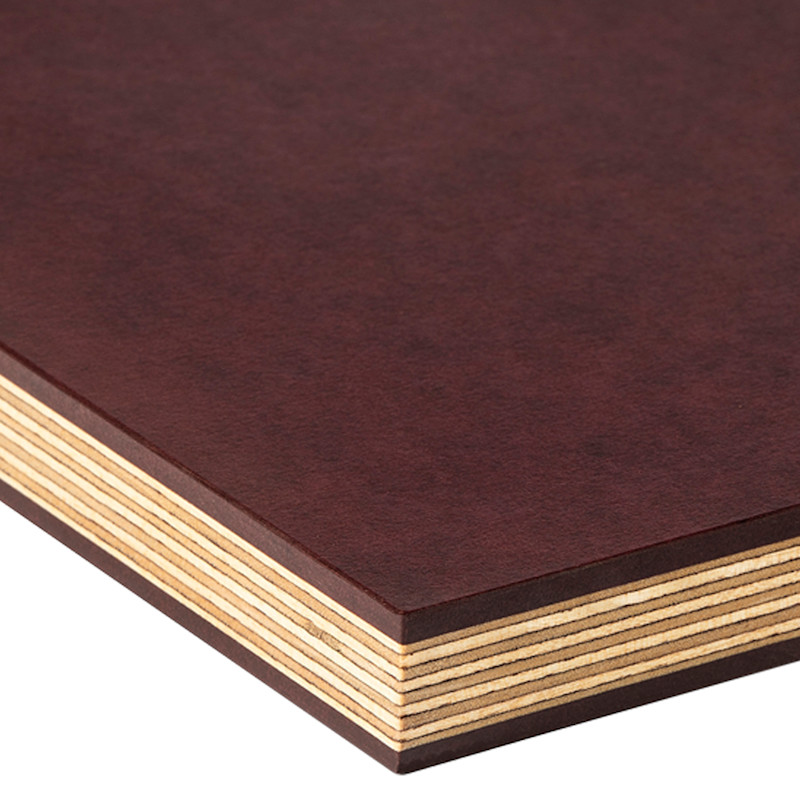

Stratum Birch Collection

Richlite Stratum Birch is an incredibly stable and balanced product that embeds Birch ply between contrasting layers of paper.

Related Projects

Applied Finishes & Sample Information

PLEASE NOTE: All Richlite panel orders are shipped with the "factory finish".

The following images are finishes that can be achieved by a professional installer or fabricator. Please consult the Richlite Fabrication Guide for more details.

Standard Richlite samples come with a Leathered Finish (shown below), excluding the following:

Honed Finish Samples: Rainier, Little Tahoma, and Black Diamond Stratum Bamboo.

Factory Finish Samples: Slate, r50, and Natural.

Requests for samples with finishes different from what is listed above are considered custom samples and will have longer turnaround time, if available.

Here is what comes in the Richlite Architectural Sample Box

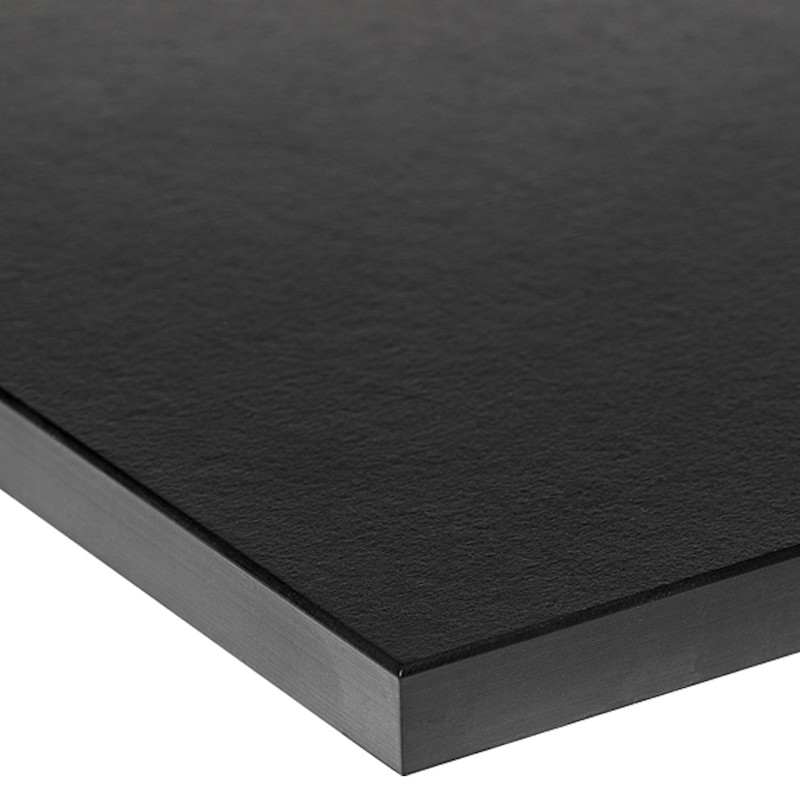

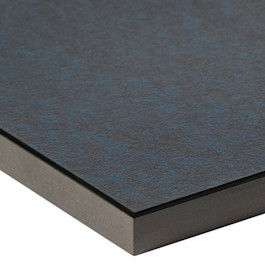

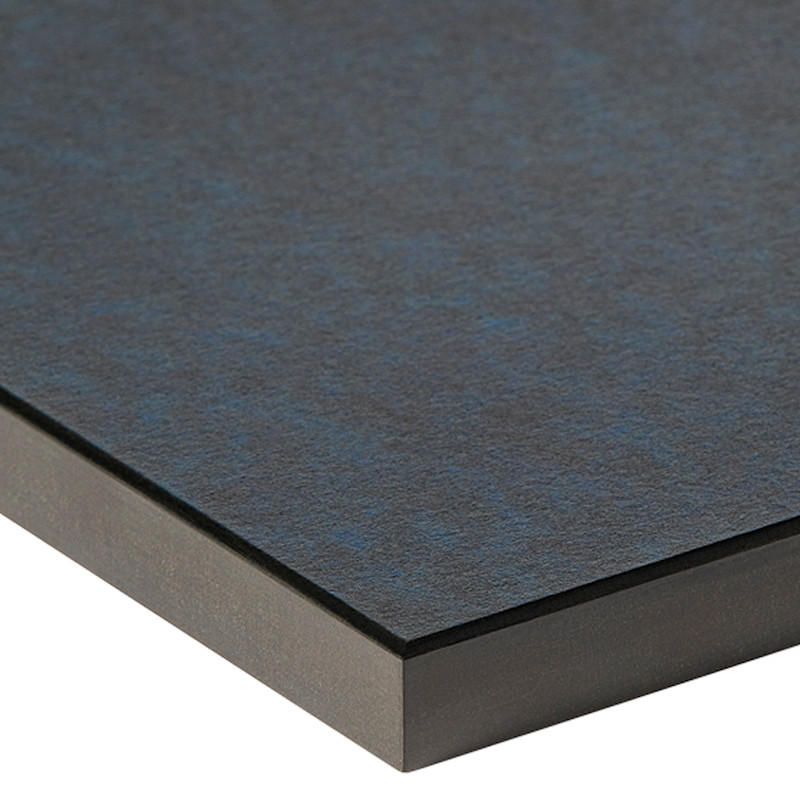

Leathered Finish

Keeps the texture of Richlite, but an added applied finish enriches the color and adds a layer of protection. The Leathered finish is the most commonly specified surface finish for interior commercial and residential projects due to its durability and aesthetics.

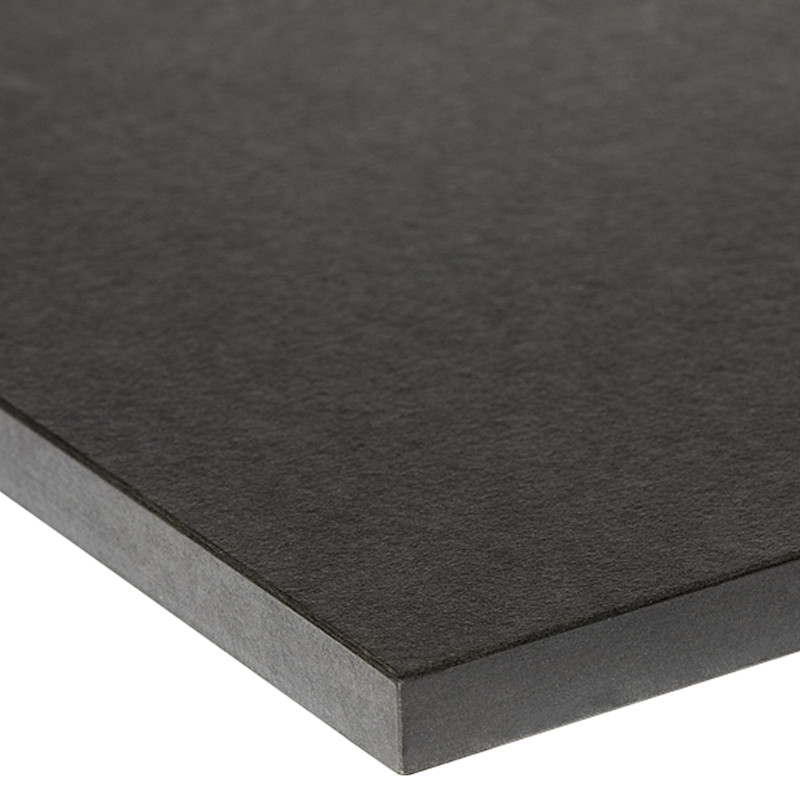

Honed Finish

The Honed finish results in a smooth, semi-gloss surface. Like with most smooth surfaces, the Honed finish will show wear sooner than the Leathered finish. This option is best for those who enjoy a polished look and appreciate that it will develop a wear pattern over time.

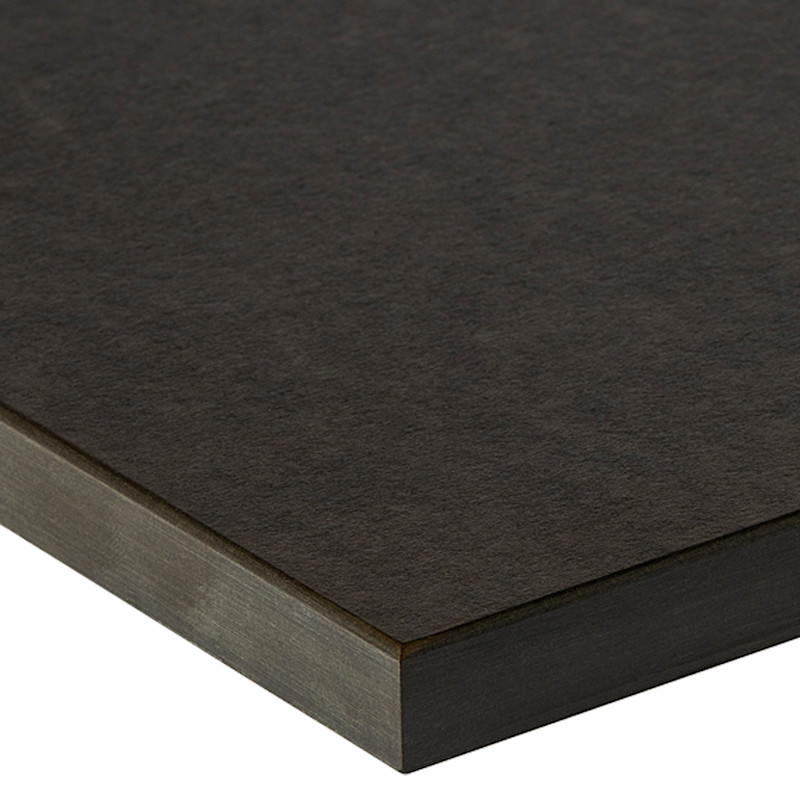

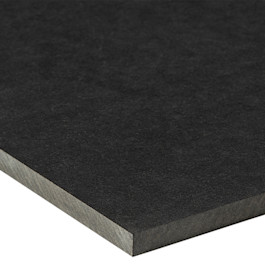

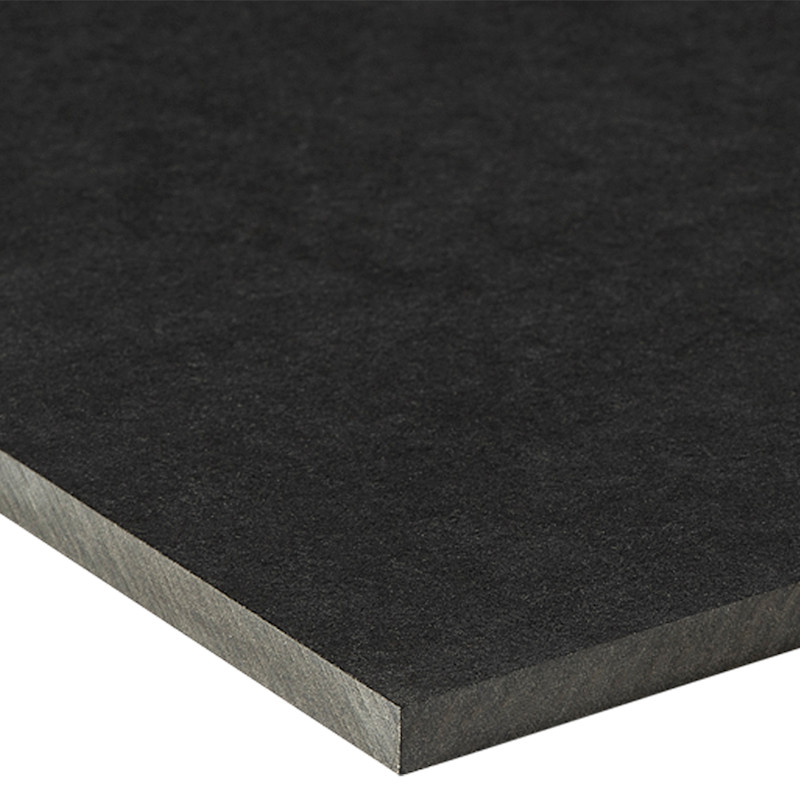

Factory Finish

This finish has a slight texture that is created in the manufacturing process. Factory-finished material is generally used within the OEM manufacturing and industrial machining industries. The Factory finish is the least commonly specified surface finish for interior architectural applications.

Possible LEED® Credits

Credits for All Colors

ID Credit 1-1.4 | Innovation & Design Process 1-4 Points for All Richlite lines

EQ Credit 4.4 | Low-Emitting Materials Composite Wood & Agrifiber Products Indoor air quality / No added urea-formaldehyde 1 Point for All Richlite lines and all products are GREENGUARD® Certified.

MR Credit 5.2 | Regional Materials 20% Extracted Processed & Manufactured Regionally Regional Materials: Base location: Tacoma, WA 98421 2 Points (1 Point in addition to MR Credit 5.1)

Color Specific Credits

MR Credit 7 | Certified Wood All colors are FSC® certified with the exception of Richlite r50 1 Point

MR Credit 4.2 | Recycled Content: 20% (post-consumer + ½ pre-consumer) Richlite Blue Canyon, Chocolate Glacier, & r100: 100% post consumer fiber Richlite r50: Minimum 50% recycled content 2 Points (1 Point in addition to MR Credit 4.1)

MR Credit 6 | Rapidly Renewable Materials All other Richlite colors minus those in MR Credit 4.2: 30% Eucalyptus Fiber 1 Point

AIA CE Course

| Product | Course Title | Credits | Sign Up |

|---|---|---|---|

| Richlite | Understanding Manufacturing, Applications and Benefits of Paper Composite Surfaces | 1 LU - HSW | Sign Up |

Technical Documents

| Title | Type | Download |

|---|---|---|

| Richlite Fabrication Guide | Fabrication Guide | Download (67.37 KB) |

| EcoCuts Richlite Countertop Fabrication Services Info Sheet | General Information | Download (1.30 MB) |

| Richlite - CSI 3-Part Spec - Master Format 04 | CSI Spec | Download (7.22 KB) |

| Richlite - CSI 3-Part Spec - Master Format 95 | CSI Spec | Download (7.17 KB) |

| Richlite ASTM C1028 Coefficient of Friction | Lab Testing | Download (16.57 KB) |

| Richlite ASTM E84 UL Labs Richlite Class A Fire Rating | Lab Testing | Download (12.34 KB) |

| Richlite ASTM E90 04 Sound Transmission .50 | Lab Testing | Download (1.77 MB) |

| Richlite ASTM E90 04 Sound Transmission .75 | Lab Testing | Download (1.72 MB) |

| Richlite Brochure | Catalog/Binder | Download (4.91 MB) |

| Richlite Cantliever Spans | General Information | Download (71.35 KB) |

| Richlite CARB 2 EPA Emission Standards | Certification | Download (41.98 KB) |

| Richlite Care Maintenance 2019 | Care & Maintenance | Download (11.30 KB) |

| Richlite cascade ordering guidelines | General Information | Download (16.00 KB) |

| Richlite CNC | Fabrication Guide | Download (9.26 KB) |

| Richlite Commercial Residential Warranty | Warranty Information | Download (3.61 KB) |

| Richlite Cutting | Fabrication Guide | Download (7.20 KB) |

| Richlite Delivery Handling Storage | General Information | Download (14.78 KB) |

| Richlite Drilling | Fabrication Guide | Download (8.80 KB) |

| Richlite Environmental Product Declaration (EPD) | General Information | Download (1.69 MB) |

| Richlite EPA 8270 Lead Phthalates | Lab Testing | Download (70.96 KB) |

| Richlite Exterior Commercial and Residential Warranty | Warranty Information | Download (3.61 KB) |

| Richlite FSC Certificate | Certification | Download (14.64 KB) |

| Richlite Greengaurd Gold Certificate Children Schools Program | Certification | Download (67.66 KB) |

| Richlite Greenguard Certificate Indoor Air Quality | Certification | Download (66.67 KB) |

| Richlite Interior Residential Warranty | Warranty Information | Download (3.60 KB) |

| Richlite JIS 2801 Antimicrobial | Lab Testing | Download (21.50 KB) |

| Richlite Kosher Certificate 2016 2017 | Certification | Download (29.89 KB) |

| Richlite Lab Top Chemical Resistance Test | Lab Testing | Download (60.42 KB) |

| Richlite Lacey Act Declaration Letter | General Information | Download (46.31 KB) |

| Richlite LEED Info | Certification | Download (10.29 KB) |

| Richlite Material Surface Options | Fabrication Guide | Download (15.66 KB) |

| Richlite MSDS | MSDS | Download (7.16 KB) |

| Richlite NSF Standard 51 Natural | Certification | Download (42.87 KB) |

| Richlite NSF Standard 51 Slate Black | Certification | Download (0.97 KB) |

| Richlite Properties | General Information | Download (48.68 KB) |

| Richlite REACH Test Report | Lab Testing | Download (25.71 KB) |

| Richlite Routing | Fabrication Guide | Download (7.39 KB) |

| Richlite Seaming Gluing Fastening | Fabrication Guide | Download (12.71 KB) |

| Richlite Sizes Weights Thickness 2018 | General Information | Download (10.45 KB) |

| Richlite HPD | General Information | Download (11.32 KB) |

| Richlite Declare Certificate | Certification | Download (85.67 KB) |

Our Value-Added Services Division

EcoCuts is the value-added services division of EcoSupply. By combining CAD software, cutting and machining services, our suite of sustainable materials and decades of experience, EcoCuts can deliver value added solutions to help you achieve your project goals.