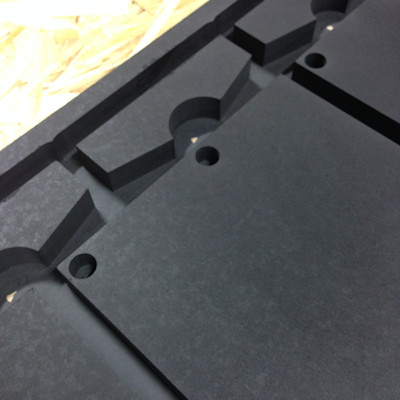

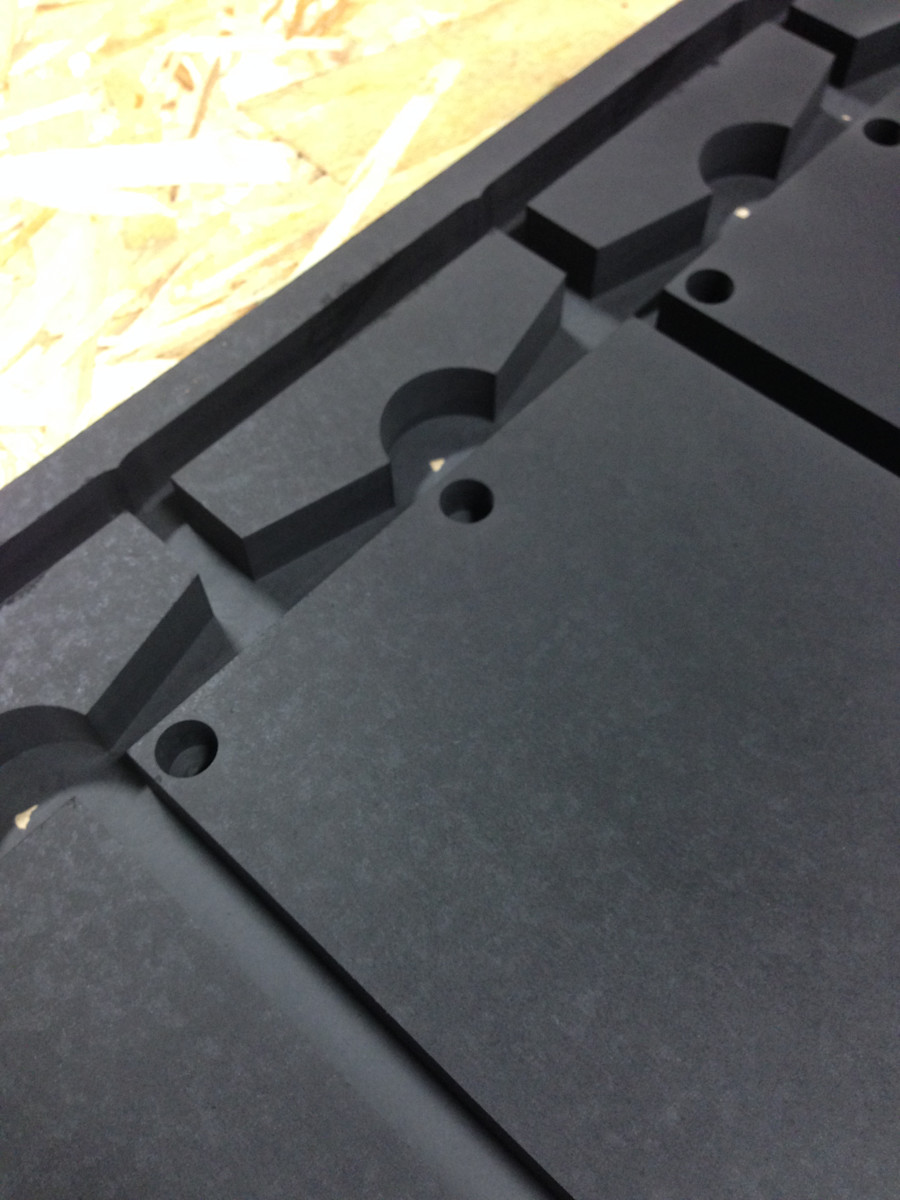

OEM / Industrial Solutions

Our products are dynamic and versatile. They have been used in everything from the aerospace and marine industries, to instrumentation as guitar fret boards, and even cladding on skateboard ramps. Mobile device cases, rail car fixtures, machinery components and food service are only some of the wide ranging industrial and OEM applications for our products. We are constantly pursuing new areas that need long lasting and durable green solutions.